Digital defect management: Why the simple approach is often the best – and how we make it possible with docu tools

Anyone who has ever tried to manage defects on a construction site using Excel lists, WhatsApp photos, email chains and various file versions knows the feeling: at some point, it just stops working. Information disappears, responsibilities become unclear, deadlines pass – and suddenly a simple defect turns into a real problem.

At the same time, many digital solutions on the market are impressively comprehensive, but also impressively overloaded: construction scheduling, resource management, procurement tools, complex rights structures.

Sounds good – until you really need it in everyday life.

For defect management, this means one thing above all else:

Too many clicks, too much complexity, too much time wasted.

Between these two extremes – chaos on the one hand and overload on the other – something crucial is missing:

A simple, clear, pure defect management solution.

That’s exactly why docu tools exists.

What is defect management – and why does it so often fail in practice?

Defect management essentially comprises five steps:

- 1. Identifying defects

- 2. Document defects

- 3. Assign responsible persons

- 4. Set deadlines

- 5. Track tasks cleanly

It sounds so simple. In reality, however, it fails because the process is not consistent, centralised or structured.

Why traditional methods fail: Excel, WhatsApp and email

Many projects start with pragmatic, low-budget solutions – which become unmanageable once there are 30–50 defects or more:

1. Information is everywhere

Photos on your mobile phone, Excel on your laptop, notes on paper, status updates via email.

2. No uniform structure

Every trade delivers differently, every site manager documents differently.

3. No traceability

Who said what and when? What was the deadline?

Often almost impossible to reconstruct.

4. Time-consuming

Reports must be created manually.

5. No control

Deadlines are missed, those responsible are not reminded.

In short:

Excel and WhatsApp work – until they don’t.

Why many digital solutions are not better

On the other hand, there are comprehensive software packages that can do ‘everything’:

Plan management, BIM, document storage, resources, calendar – and somewhere in there, a defect management module.

The problem:

- Too complex: a simple task requires twenty clicks.

- Too expensive: you pay for many features you never need.

- Lack of focus: Defect management is often only a side issue. There is a lack of depth and detail – precisely where they would be crucial.

The result: a real gap remains for such a critical issue as defect management.

How docu tools solves defect management – without the complexity of traditional software

We did not develop docu tools to be able to do ‘everything’, but to be able to do the important things perfectly. Our defect process is clear, structured, fast – and specifically designed for practical use.

Here are the functions that are missing in many systems, but are crucial in reality:

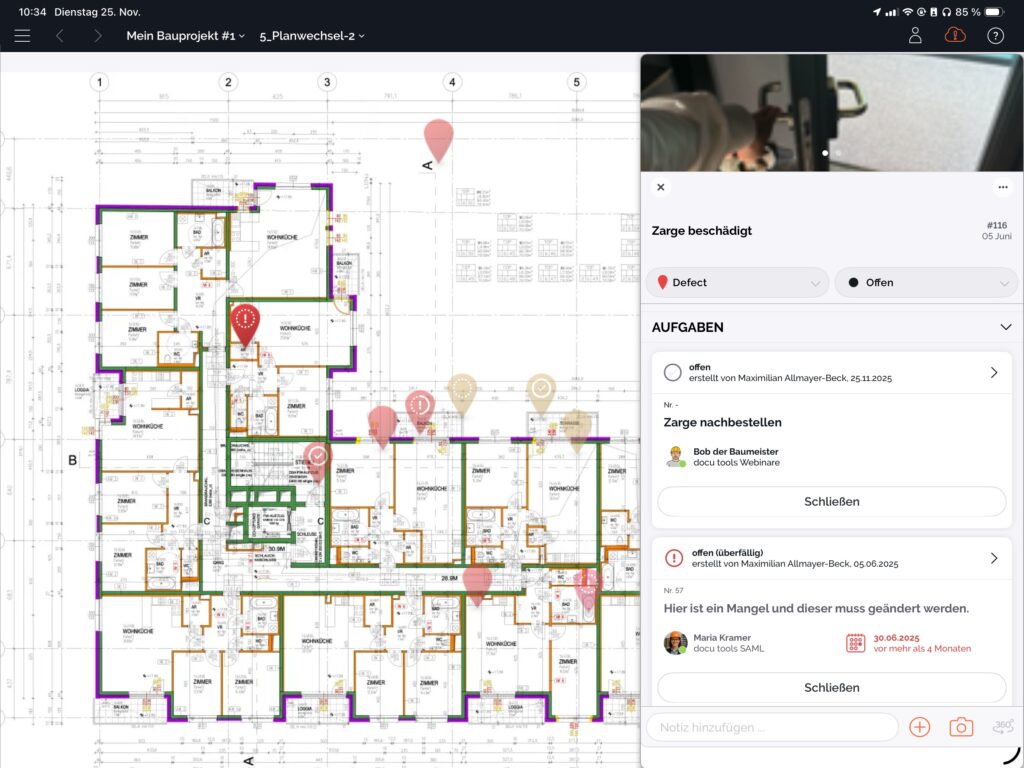

1. One mark on the plan – several tasks in the same context

Instead of placing five markers in the same location, we offer:

- 1 Pin = the context

- multiple tasks = specific deficiencies

This means:

- Less chaos

- Clearer overviews

- Clean structure for building supervision, main contractors and subcontractors

A significant difference compared to many other tools.

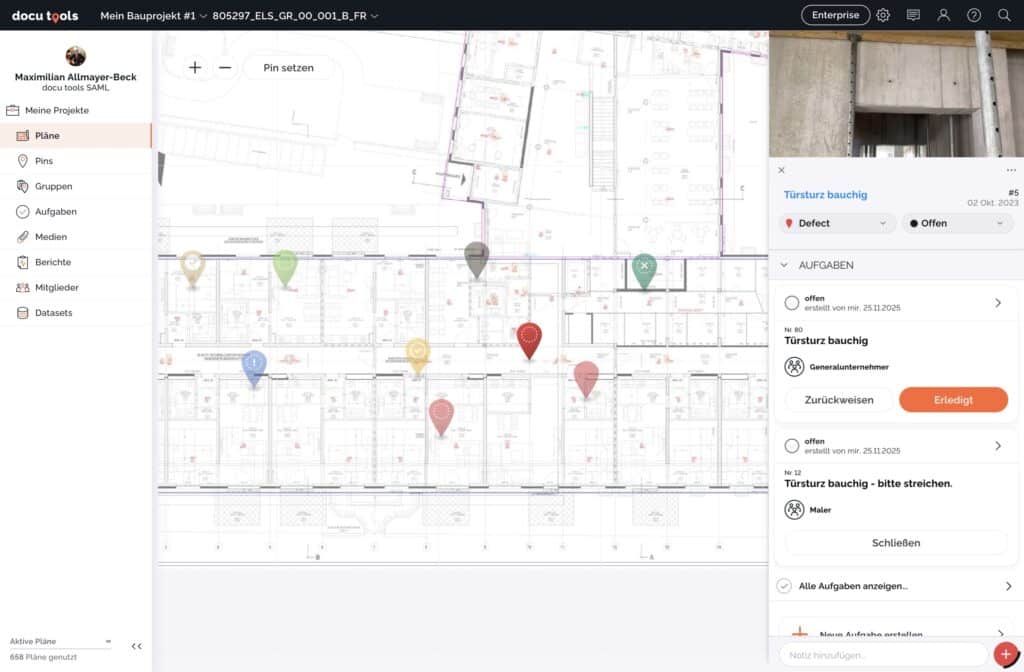

2. The actual construction workflow: Building supervision → General contractor → Subcontractor → General contractor → Building supervision

The standard workflow in the construction industry – impossible to map in many systems, but neatly supported by us.

Example:

- 1. Building inspectorate creates Pin + task, assigns it to the main contractor.

- 2. Main contractor checks and creates a second task in the same Pin.

- 3. This is assigned to the subcontractor.

- 4. The subcontractor completes the task and reports back to the main contractor.

- 5. The main contractor checks and only then reports to the building inspectorate.

Result:

- Clear responsibilities

- Genuine control

- Complete transparency

- Everything documented in one pin

- Audit-proof stored history

This is precisely why general contractors particularly value docu tools.

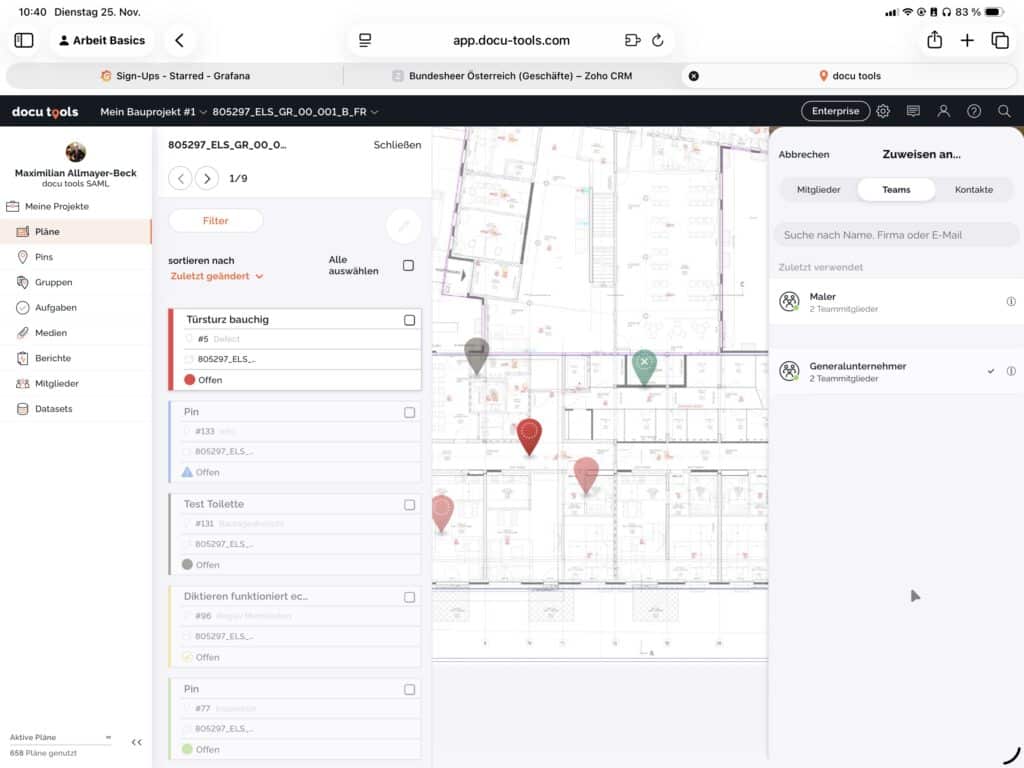

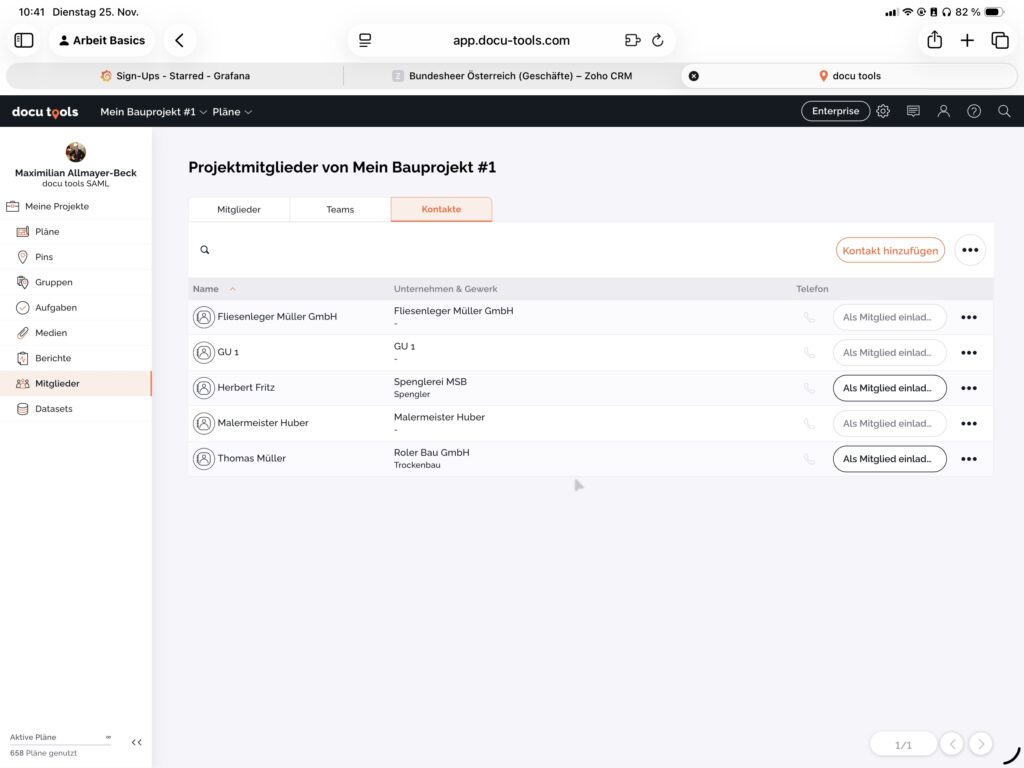

3. Teams – because projects are not made up of individuals

We enable you to combine several people into a team:

- Tasks can be assigned to a team

- All team members see the same tasks

- Anyone can document and complete defects

This is a huge advantage, especially for larger projects.

4. Speed: Record a defect in around 10 clicks

It sounds trivial, but it’s crucial in everyday life.

We need around ten clicks to record a complete defect:

- Set pin

- Title

- Description

- Trade

- Responsible person

- Due date

- Photo(s)

When you have to document 60 or more points per day, every additional pair of clicks makes a difference – especially during inspections with the client and subcontractors.

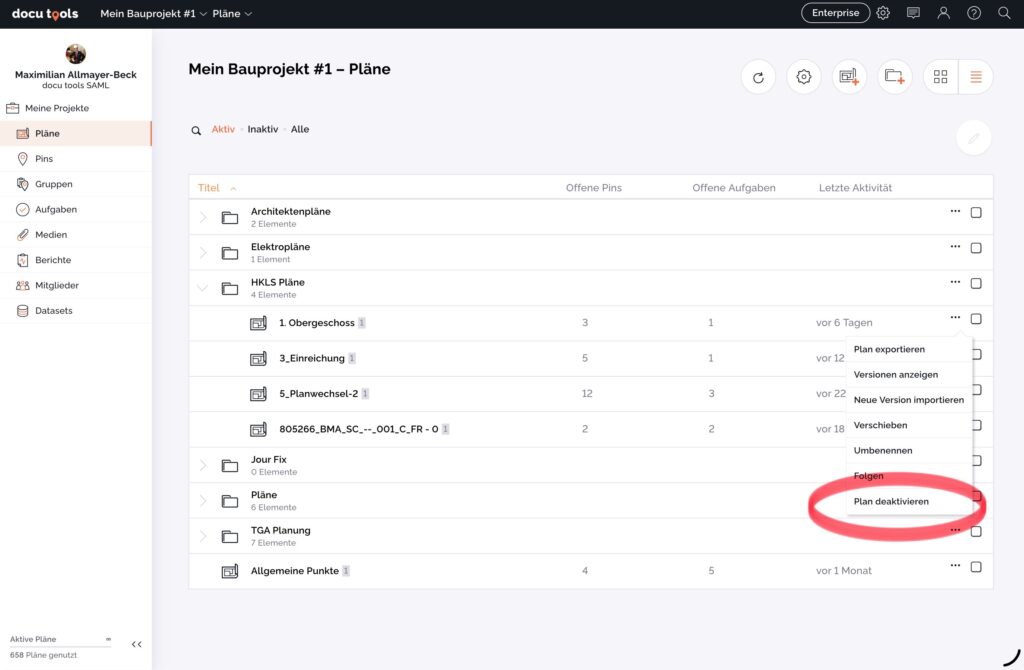

5. Audit compliance: Nothing can be deleted with us

A defect report is legal evidence. Therefore, our policy is as follows:

- Pins cannot be deleted.

- Tasks cannot be deleted.

- Every change is traceable.

- Every step has a timestamp.

This ensures maximum legal certainty – without any room for interpretation.

6. Digital process + hybrid process – both possible

Not every subcontractor enjoys working digitally – that’s why we support both worlds:

Digital members

- work directly in the software

- view their tasks

- report digitally

- upload photos

Contacts (without login)

- Receive tasks via reports

- Reports can be shared via link

- Contacts can be converted into members at any time later

This allows everyone to remain flexible – especially in the early stages of a project.

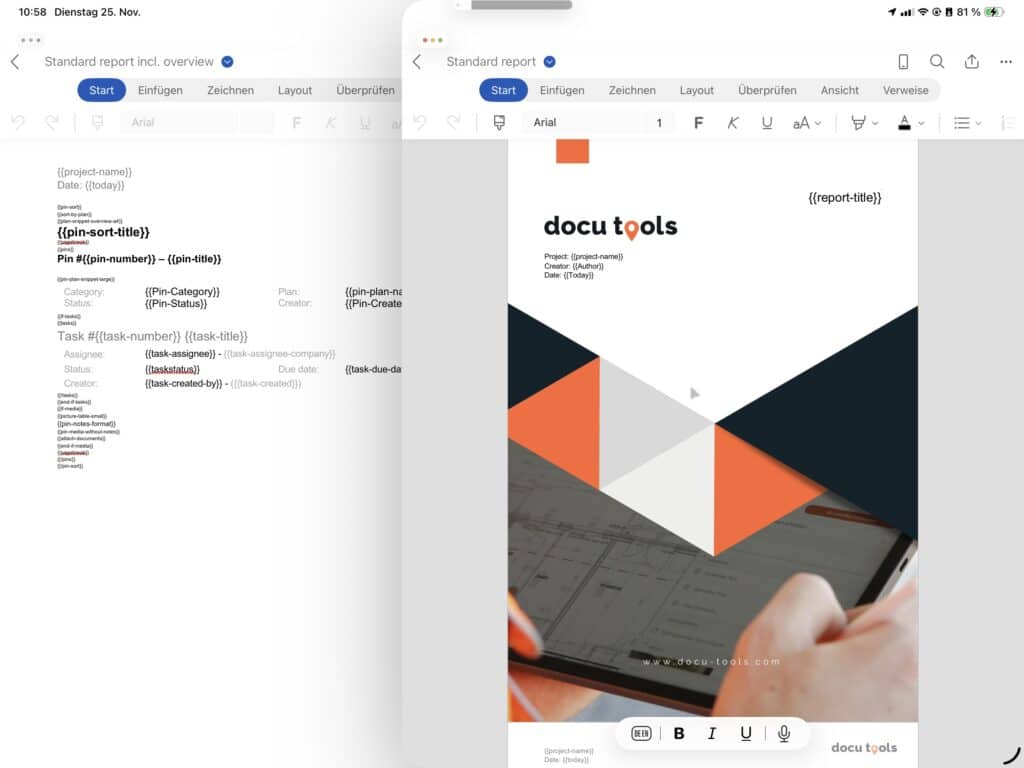

7. Custom report templates

Defect reports often have to meet legal requirements – for example, VOB reference in Germany.

With docu tools, report templates can be freely designed using Word and Excel:

- Title pages

- Layout

- Headers and footers

- CI design

- Variable fields

- Structured content from pins

This ensures that your defect reports are always legally compliant and visually professional.

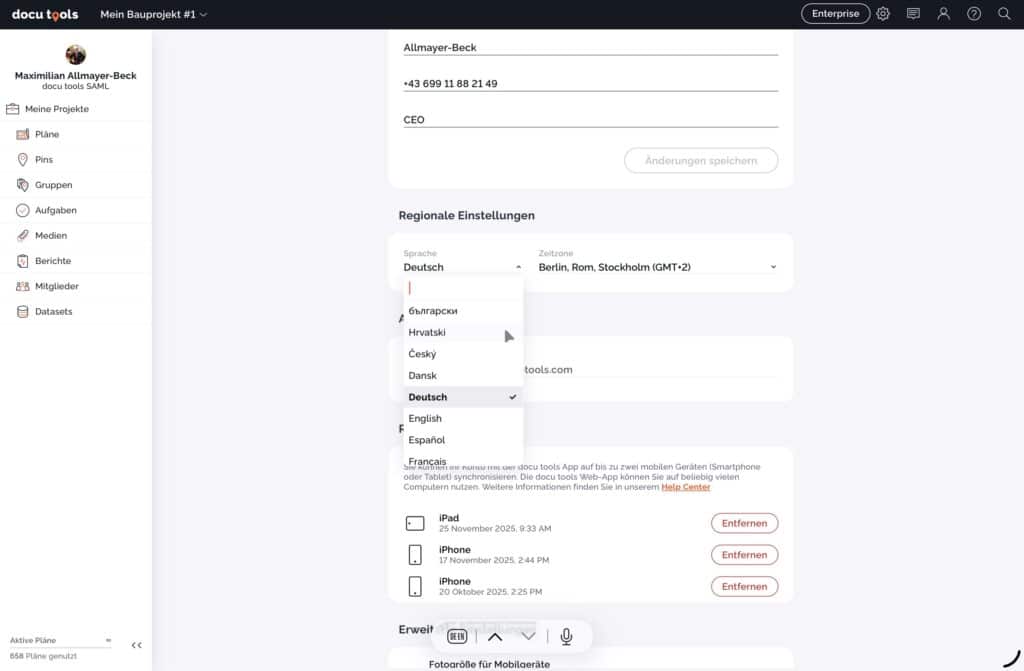

8. Internationally applicable – a defect process that works everywhere

docu tools is currently used in Germany, Austria, Switzerland, Poland and many other countries.

The reason is simple: our defect process is not based on national standards, but on logic.

With freely customisable report templates, flexible task structures and clear pin logic, docu tools can be adapted precisely to local requirements in any country – regardless of whether:

- VOB in Germany

- ÖNORM in Austria

- Customer-specific specifications in Poland

- International project standards

Or completely customised layouts that only apply to a specific company.

This means that docu tools works wherever defects need to be recorded, communicated and tracked – regardless of language, documentation culture or legal requirements.

Why docu tools is different

We don’t say ‘we are better’.

We say: We focus on the essentials – defect management.

While other tools:

- Have 40 functions that no one uses

- Require complex training

- Overwhelm subcontractors

- Are expensive

- Are slow to operate

we rely on:

- Simplicity

- Speed

- Flexibility

- Legally compliant documentation

- Clear collaboration (members + contacts)

This does not make us larger, but more focused. And that is precisely our strength.

Conclusion: Defect management is not a feature. It is a process.

Many tools view defect management as an additional module.

We see defects as a core process that significantly determines success or chaos.

With docu tools, we create:

- Clear responsibilities

- Rapid recording

- Traceable histories

- Transparent communication

- Legally compliant documentation

- Flexible collaboration

- Easy operation

Without Excel chaos.

Without WhatsApp messages.

Without unnecessary software functions.

References & Customer Stories

If you would like to see how docu tools is used in real projects – from international infrastructure projects to regional construction companies – take a look at our case studies.

There, our customers themselves demonstrate how they accelerate defect processes, create clarity and save hundreds of working hours.

Try it for yourself: setting up a project in docu tools takes less than ten minutes – and then you can start documenting on site straight away.