Acceptance on site: definition, procedure & modern practice

Acceptance is one of the most important milestones in any construction project. It marks not only the end of the construction work, but also the moment when liability, responsibility and risk are transferred from the contractor to the client. Errors or missing documentation can be costly here — both legally and financially.

This article provides a clear overview of the legal basis, practical implementation and typical stumbling blocks. We also show how modern projects now document approvals digitally, thereby avoiding disputes.

I. Why building inspection is so critical

There is hardly any other moment that builders, general contractors and subcontractors focus on as much as the acceptance inspection. This is because it determines:

- the commencement of the warranty period

- the due date of the final invoice

- the transfer of responsibility

- the question of who is liable for damage or delays

A single missing signature, an unclearly worded defect or incomplete documentation can lead to lengthy disputes later on. This makes it all the more important to have a structured, clearly documented process.

II. What does ‘acceptance’ mean? – The legal definition

According to Section 640 of the German Civil Code (BGB) (or comparable regulations in Austria and other countries), acceptance refers to the physical receipt of the work combined with a declaration that the service is essentially in accordance with the contract.

This has important legal consequences:

- Transfer of risk: The risk of damage is transferred to the client.

- Commencement of warranty: Claims for defects shall only commence from this point in time.

- Reversal of the burden of proof: After acceptance, the client must prove that defects were caused by the contractor.

- Payment due date: The final invoice can be settled from this date.

Therefore, the following applies: No acceptance without clear documentation.

III. Types of acceptance

In the construction industry, a distinction is made between different forms of acceptance. They all have legal consequences, even if they come about in different ways:

1. Formal acceptance

The classic variant: a joint inspection, a report, the signatures of all parties involved.

2. Tacit (implied) acceptance

It arises when a client uses a work without expressly declaring acceptance.

Example: When a builder moves into a building and lives there even though no formal acceptance has taken place.

3. Partial acceptance

In the case of large-scale projects, individual construction phases or trades are approved at an early stage.

Advantage: clear accountability and early warranty commencement.

4. Technical approval

Inspection of individual technical systems: heating, ventilation, electrical, lifts, etc.

5. Final acceptance

The final step, which affects the entire work.

Clear acceptance forms can help to avoid disputes — provided that they are documented and comprehensible.

IV. Typical problems during acceptance inspections

Despite clear regulations, errors occur in practice. Common causes:

- Incomplete documentation (photos on private mobile phones, Excel lists without assignment)

- Time pressure on the construction site

- Unclear descriptions of defects (‘please rectify’ instead of specific findings)

- No responsible persons defined per defect

- Disagreement between general contractor, subcontractor and client

- Lost minutes or missing signatures

- Defects are not tracked

These errors cost time, money and nerves. However, many of them can be avoided by following a structured process.

V. Procedure for a professional acceptance inspection

A clean acceptance process always follows the same pattern — regardless of whether it is a small job or a large project.

1. Preparation

• Review plans, specifications and contracts

• Identify outstanding payments

• Invite necessary participants

2. Joint inspection

All points shall be inspected on site. Important findings must be recorded immediately in writing and with photographs.

3. Documentation of defects & remaining work

With photos, clear descriptions, location, trade and responsibility.

4. Set deadlines

Realistic, documented deadlines must be set for each trade.

5. Signatures and minutes

Without a signed protocol, there is no legally binding acceptance.

6. Handover to the client

After acceptance, the warranty period begins and the final invoice can be issued.

This creates audit-proof, complete documentation – without any additional effort.

VI. Checklist: What should be included in an acceptance report?

A complete acceptance test shall include at least:

- Project / Construction phase

- Date and parties involved

- trades

- Defects identified (with photos)

- Clearly defined residual services

- responsibilities

- Deadlines for rectification

- Information on functional testing of technical systems

- Signatures of all parties

- Notice of commencement of the warranty period

The more complete the minutes, the less dispute there will be later.

VII. Inspections in practice – why digital is the new standard

Many inspections are still carried out using paper lists, Excel spreadsheets and photos on mobile phones. This inevitably leads to:

- duplication of work

- unclear allocations

- missing documentation

- long coordination loops

- Disputes due to lack of evidence

Modern construction projects therefore rely on digital acceptance processes in order to:

- document everything centrally

- Clearly assign defects

- Automatically track deadlines

- Having photos and plans in one place

- Generate logs automatically

This makes acceptance faster, clearer and audit-proof.

VIII. Example from construction site practice

In the interior construction of large buildings, it is common for 200–400 points per trade to be accumulated during the final acceptance inspection. Several parties involved (main contractor, subcontractor, client, planner) are under time pressure at the same time.

Problems often arise because:

- Defects are not clearly described

- Responsibilities are lacking

- Supplements arise because services were incorrectly assessed.

- Photos are not assigned to the correct room or trade

Digital systems dramatically reduce these errors:

A defect is recorded → photo taken → trade assigned → deadline set → automatically transferred to the report.

No media breaks, no paper, no chaos.

IX. How docu tools improves acceptance

Professional acceptance stands and falls with documentation. This is exactly where docu tools comes in – with functions that have been specially developed for the requirements of construction sites:

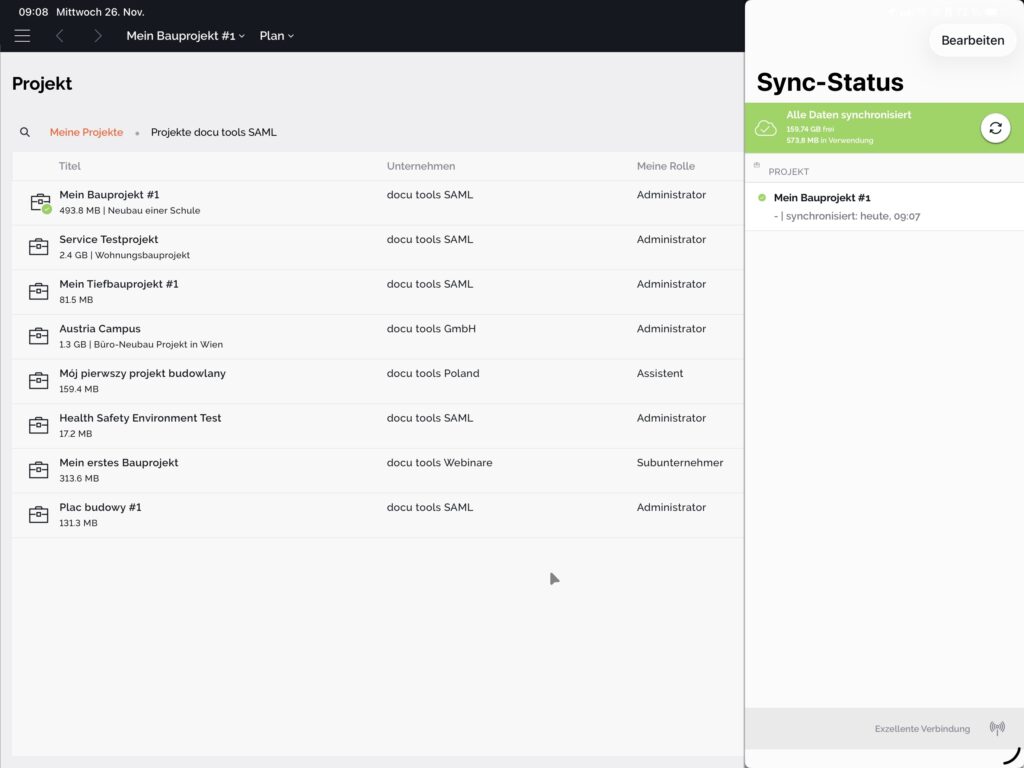

Mobile apps (offline capability)

All acceptance points can be recorded directly on site, even without an internet connection; all data is synchronised to the cloud later.

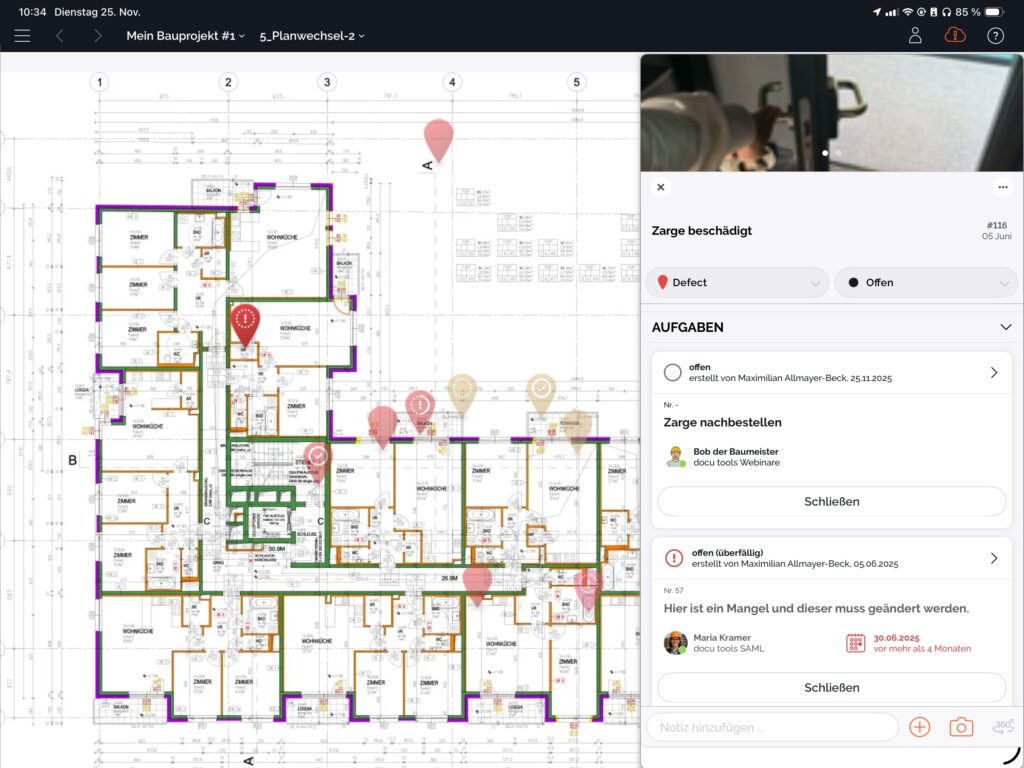

Pins with photos and notes

Each defect or point of deduction is clearly marked on the digital plan, with photographic documentation and comments.

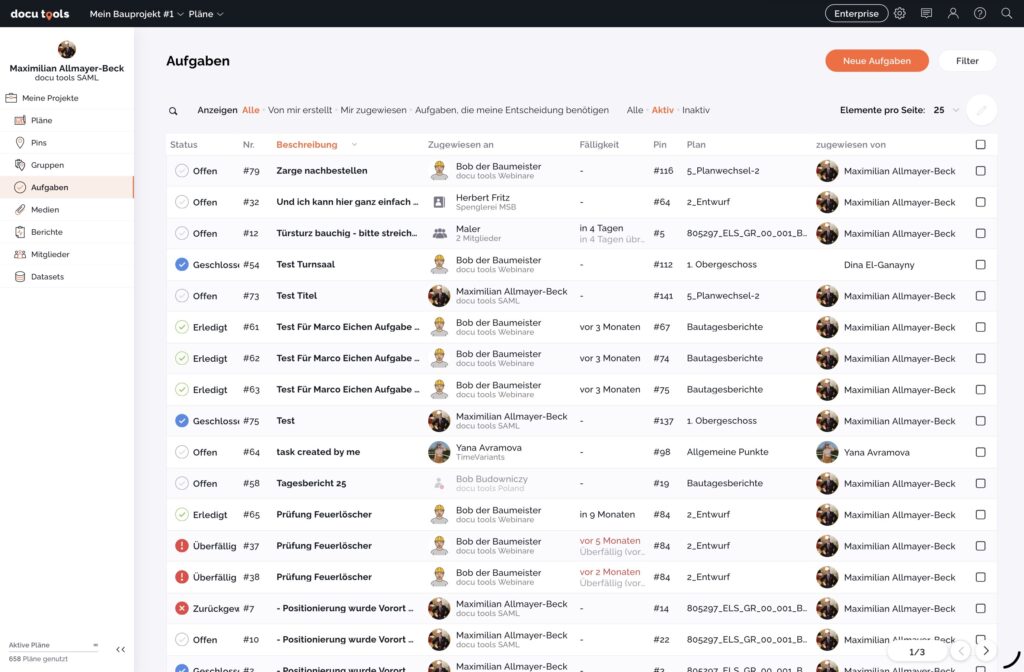

Tasks per trade with due date

Clear responsibilities, clear deadlines and automatic reminders reduce discussions and delays.

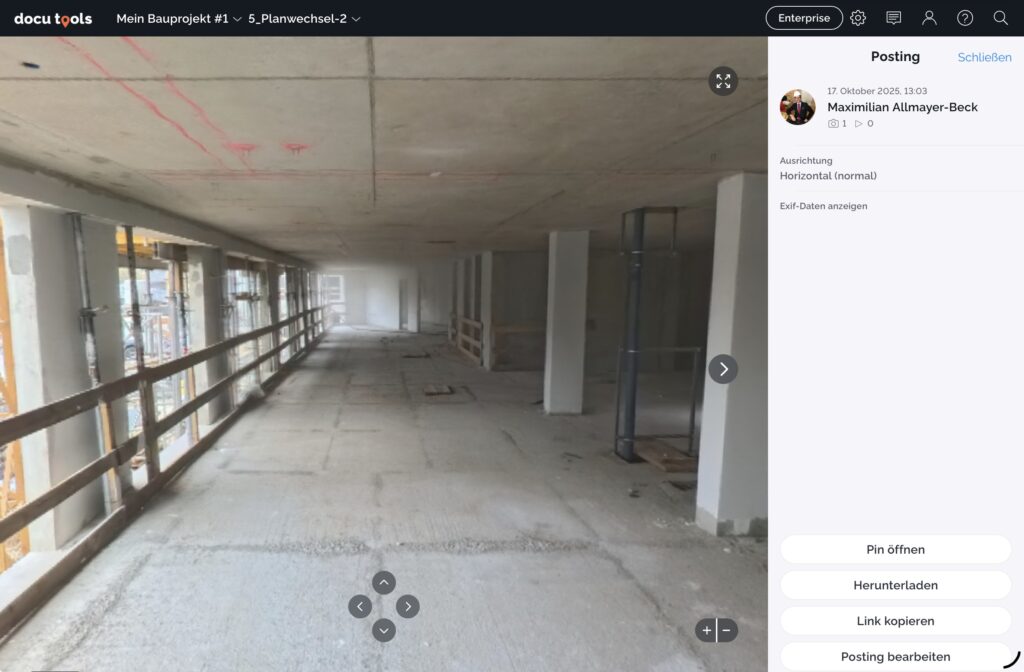

360° photos for interim acceptance inspections

Ideal for completely recording the condition of entire rooms or construction phases before they are closed or further construction takes place.

Audit-proof history

Every action is logged, nothing can be deleted; ideal for legal and liability issues.

Perfect traceability for contractors, subcontractors and builders

Everyone involved sees the same information, updates and deadlines – without Excel chaos or email chains.

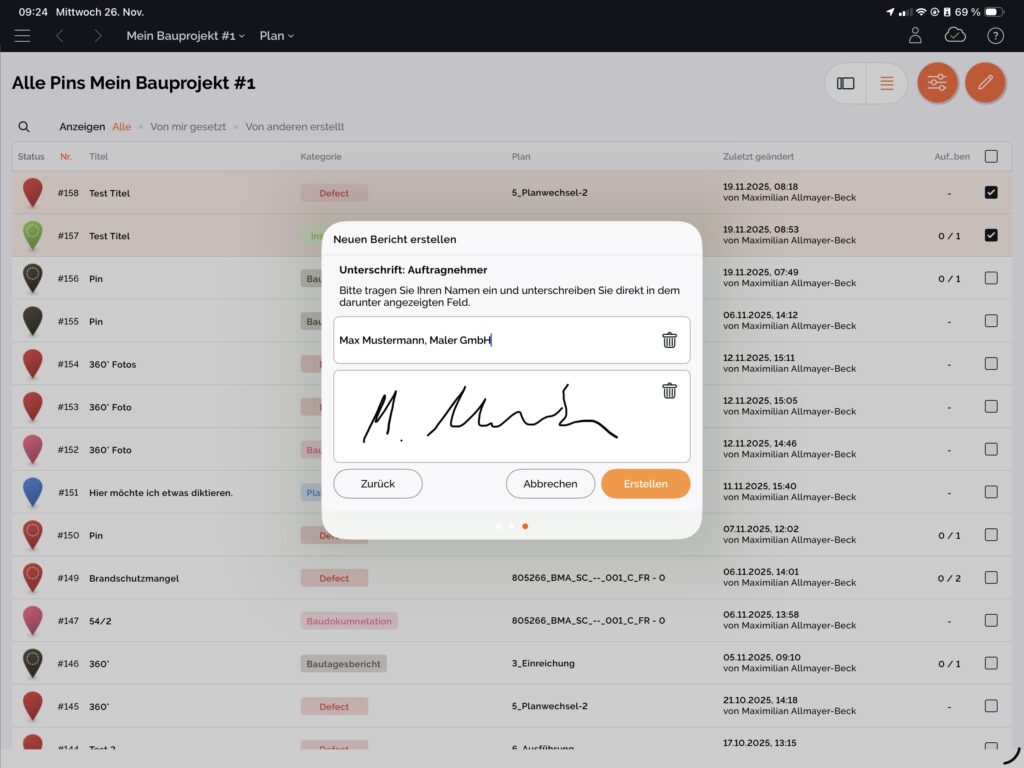

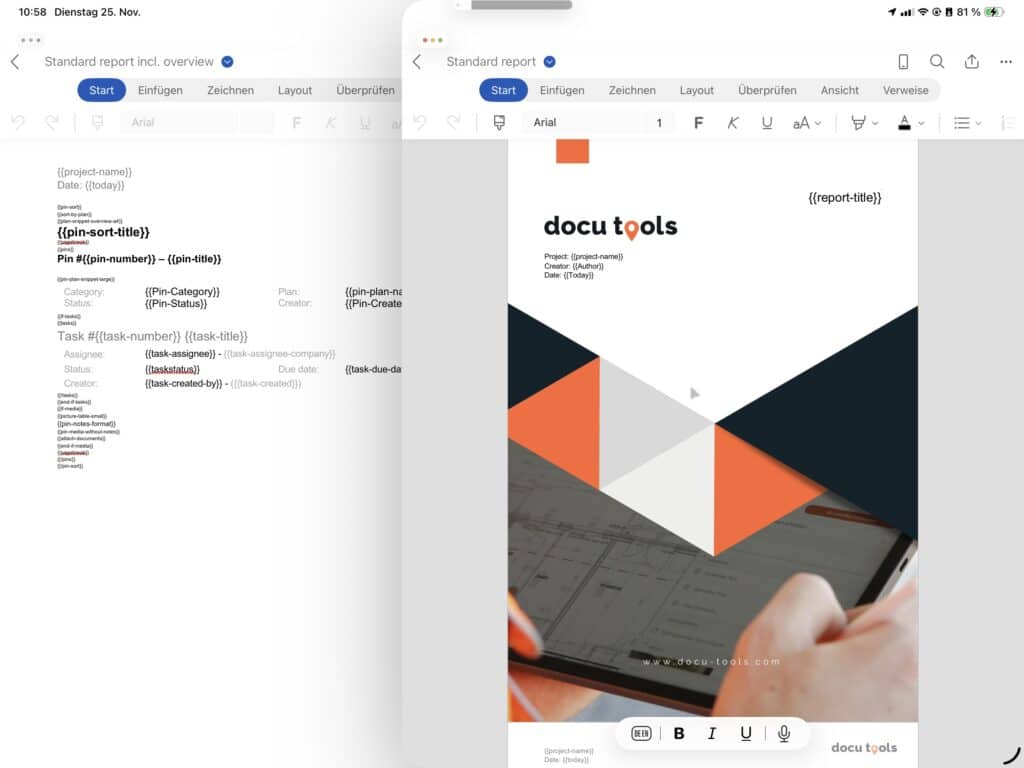

Acceptance reports & reports (Word templates & digital signature)

Minutes can be created in docu tools using customisable Word templates. The completed acceptance report can be signed digitally on site, completing the entire process – without paper and without any follow-up work in the office.

This not only speeds up the acceptance process, but above all makes it legally compliant and transparent.

X. Conclusion

From a legal and practical perspective, acceptance is one of the most important steps in the entire construction process. Mistakes at this stage are costly and often cannot be corrected until it is too late.

Working in a structured manner, documenting clearly and using modern digital tools reduces risks, saves time and ensures transparency for all involved.

Digital inspections are not a trend, but have become standard practice — and a decisive factor for successful construction projects.